The Hino 200 Series trucks are known for their relatively quiet operation compared to some other trucks in their class. This is achieved through several design features aimed at reducing noise and improving cabin comfort for the driver and passengers. Here are some factors that contribute to the quietness of the Hino 200 Series:

1. Engine Design: Hino engines are known for their smooth operation and efficient combustion, which helps in reducing noise levels. Modern diesel engines, including those used in the Hino 200 Series, are designed with noise reduction in mind.

2. Sound Insulation: The cabin of the Hino 200 Series trucks is typically equipped with sound insulation materials to dampen engine and road noise. This includes insulation in the firewall, doors, and ceiling.

3. Vibration Control: Vibration dampening techniques are used to minimize engine and drivetrain vibrations that can contribute to cabin noise.

4. Exhaust System: The exhaust system is designed to minimize noise emissions while maintaining efficient performance.

5. Aerodynamics: Efficient aerodynamic design helps reduce wind noise at highway speeds.

Overall, the combination of these factors contributes to a quieter driving experience in the Hino 200 Series trucks, making them suitable for urban environments where noise pollution is a concern.

Traction control is a technology in vehicles designed to improve stability and control by preventing wheelspin during acceleration. It’s particularly useful in situations where traction is limited, such as on slippery or uneven surfaces. Here’s how traction control typically works:

1. Wheel Speed Sensors: Traction control systems utilize wheel speed sensors to monitor the rotational speed of each wheel.

2. Comparison of Wheel Speeds: The system compares the rotational speeds of the wheels. If one wheel is spinning significantly faster than the others (indicating wheelspin), the traction control system intervenes.

3. Braking Intervention: To reduce wheelspin, the traction control system selectively applies braking force to the spinning wheel(s). This helps transfer torque to the wheels with better traction.

4. Throttle Control: In some systems, traction control can also reduce engine power by modulating the throttle to prevent excessive wheelspin.

5. Stability Enhancement: By preventing wheelspin, traction control enhances vehicle stability and control, especially during acceleration on slippery surfaces or when cornering.

Traction control is typically integrated with other vehicle stability systems such as Electronic Stability Control (ESC). ESC uses sensors to detect and reduce the loss of traction (skidding) during cornering or evasive maneuvers by selectively braking individual wheels and adjusting engine power. In summary, traction control is a valuable safety feature that helps drivers maintain control of their vehicles in challenging driving conditions, ultimately improving safety and stability

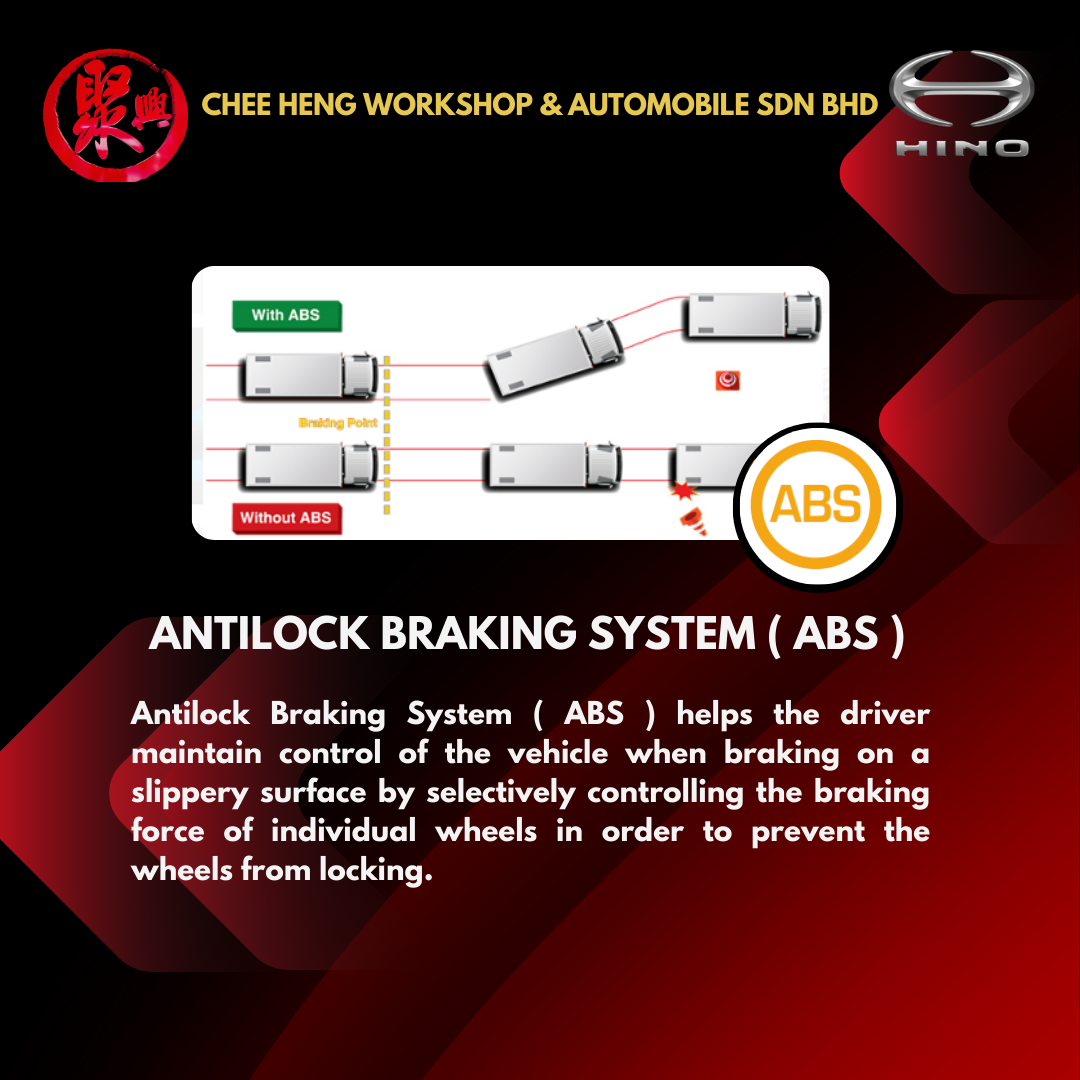

ABS stands for Anti-lock Braking System. It is a safety feature in vehicles designed to prevent wheels from locking up during braking, thereby maintaining traction with the road surface and allowing the driver to retain steering control. Here’s how ABS typically functions:

1. Wheel Speed Sensors: ABS relies on sensors at each wheel that monitor its speed.

2. Detection of Wheel Lockup : When the brakes are applied suddenly and the ABS detects that a wheel is on the verge of locking up (typically when it slows down more rapidly than the other wheels), it activates.

3. Pulsating Braking: ABS works by rapidly pulsating the brakes on and off several times per second. This pulsating action prevents the wheel from locking up and allows it to continue to rotate, maintaining traction with the road.

4. Steering Control: By preventing wheel lockup, ABS helps the driver maintain steering control even under heavy braking. This is crucial in emergency braking situations or when braking on slippery surfaces.

5. Integration with Stability Control: ABS is often integrated with Electronic Stability Control (ESC) systems to enhance overall vehicle stability. ESC can selectively apply brakes to individual wheels and adjust engine power to help the driver maintain control in challenging driving conditions.

The benefits of ABS include shorter stopping distances on most road surfaces, improved steering control during braking, and reduced risk of skidding or losing control. It is now a standard safety feature on most modern vehicles and plays a significant role in preventing accidents by allowing drivers to maintain better control during emergency braking maneuvers.

The Hino 200 Series refers to a line of medium-duty commercial trucks produced by Hino Motors, a Japanese manufacturer. These trucks are known for their reliability, efficiency, and versatility, catering to various industries such as logistics, construction, and distribution. Hino offers different models within the 200 Series, each designed to meet specific needs in terms of payload capacity, engine power, and overall configuration.

Vehicle Stability Control (VSC), also known as Electronic Stability Control (ESC), is an advanced safety feature designed to help vehicles maintain stability and prevent skidding or loss of control in hazardous situations. Here are some key points about Vehicle Stability Control:

1. Functionality: VSC constantly monitors the vehicle’s movement and compares it with the driver’s steering inputs. If it detects a loss of traction or a deviation from the intended path (such as oversteer or understeer), it can intervene to help the driver regain control.

2. Components: The system uses sensors (such as wheel speed sensors, steering angle sensors, yaw rate sensors, and lateral acceleration sensors) to gather data about the vehicle’s dynamics. It then uses this information to apply individual brakes and adjust engine power as needed to stabilize the vehicle.

3. Activation: VSC typically activates automatically when it senses a potential loss of control. This intervention happens seamlessly and is intended to be imperceptible to the driver in normal driving conditions.

4. Benefits: The primary benefits of VSC include enhanced vehicle safety, particularly in adverse weather conditions (such as rain, snow, or ice) or during emergency maneuvers. It helps reduce the risk of skidding, sliding, or rollover incidents.

5. Regulations: Many countries have mandated VSC on new vehicles due to its proven effectiveness in preventing accidents. It is considered a standard safety feature in modern cars and trucks.

6. Integration: VSC works in conjunction with other safety systems like Anti-lock Braking System (ABS) and Traction Control System (TCS) to provide comprehensive vehicle stability management.

Overall, Vehicle Stability Control is a crucial technology that enhances vehicle safety by assisting drivers in maintaining control during challenging driving conditions or emergency situations.

The Hino 200 Series trucks are known for their durability and comfort, which extends to their suspension systems designed to minimize vibration and enhance ride quality. Here are some features and technologies typically associated with the suspension systems of the Hino 200 Series trucks:

1. Leaf Springs: Many models in the Hino 200 Series use robust leaf spring suspension systems. Leaf springs are known for their ability to absorb shocks and vibrations effectively, providing a stable and comfortable ride even when the truck is fully loaded.

2. Torsion Bar Suspension: Some variants may feature torsion bar suspension systems. These systems use a torsion bar instead of traditional coil or leaf springs to provide suspension support. They can offer a smoother ride and reduce vibrations compared to leaf springs.

3. Shock Absorbers: All models are equipped with shock absorbers (dampers) that help to dampen vibrations and bumps from uneven road surfaces. These shock absorbers are designed to enhance stability and comfort by controlling the movement of the suspension.

4. Frame Design: Hino trucks are renowned for their strong ladder frame chassis designs, which contribute to overall stability and reduce vibrations transmitted to the cabin. The robust frame construction also enhances the truck’s durability and load-carrying capability.

5. Cab Mounting: The mounting of the cab onto the chassis is also engineered to minimize vibrations and noise transmission. This helps in providing a quieter and more comfortable environment for the driver and passengers.

6. Driver Comfort: Hino places a strong emphasis on driver comfort, recognizing that reduced vibration and a smoother ride contribute to less driver fatigue during long hours on the road.

Overall, the suspension systems of the Hino 200 Series trucks are designed to deliver a balance of robustness and comfort, effectively reducing vibrations and enhancing overall ride quality for both the driver and occupants. This contributes to the trucks’ reputation for reliability and driver satisfaction in various commercial applications.

Side door beams are structural components integrated into vehicle doors to enhance occupant safety in the event of a side impact collision or rollover. These beams are typically made from high-strength materials such as steel or sometimes aluminum, and they serve several important functions:

1. Impact Protection: The primary purpose of side door beams is to absorb and distribute impact forces during a crash. They help to maintain the structural integrity of the vehicle’s passenger compartment, reducing the likelihood of intrusion into the cabin area.

2. Occupant Protection: By reinforcing the sides of the vehicle, side door beams help to protect occupants from direct impact and from being ejected during a collision. This is particularly crucial in side collisions where vehicles are more vulnerable due to less space and protection compared to the front and rear.

3. Rollover Stability: Side door beams also contribute to the overall stability of the vehicle structure in the event of a rollover. They help to maintain the shape and integrity of the doors, reducing the risk of collapse and providing additional protection to occupants.

4. Regulatory Compliance: Many countries have regulations and safety standards that require vehicles to have reinforced side door beams to enhance occupant safety. Manufacturers design and test these beams to meet or exceed these stringent requirements.

5. Design and Integration : Modern vehicles often incorporate multiple layers of protection in their side doors, including impact-absorbing materials and advanced engineering techniques to optimize safety without compromising vehicle weight or usability.

Overall, side door beams are critical safety features that contribute significantly to the overall crashworthiness of vehicles, ensuring that occupants are better protected in the event of side impacts or rollover accidents.

The front under protection on the Hino 200 Series trucks refers to a structural component designed to protect the vehicle’s undercarriage, particularly the front end, from damage due to road debris, obstacles, or off-road conditions. Here are some key aspects and features related to the front under protection in the Hino 200 Series trucks:

1. Material and Construction: Typically made from robust materials such as steel or heavy-duty composite materials, the front under protection is engineered to withstand impacts and provide a shield against rocks, gravel, branches, and other debris encountered during both on-road and off-road driving.

2. Design and Coverage: It is designed to cover critical components under the front of the vehicle, including the engine, transmission, and possibly other mechanical systems depending on the specific model and configuration. This helps to prevent damage that could impair vehicle performance or lead to costly repairs.

3. Off-Road Capability: Many models in the Hino 200 Series are designed for versatile use, including light off-road applications such as construction sites or rural areas. The front under protection enhances the truck’s ability to navigate rough terrain without risking damage to essential components.

4. Integrated Design: The front under protection is often integrated into the chassis design, ensuring it does not compromise ground clearance excessively while providing sufficient protection. It may feature access points for maintenance and service tasks, allowing technicians to inspect and service components without full removal.

5. Safety and Durability: Besides protecting mechanical components, the front under protection contributes to overall vehicle safety by reducing the risk of damage that could potentially lead to operational failures or compromised vehicle stability.

In summary, the front under protection in the Hino 200 Series trucks plays a crucial role in safeguarding critical components, enhancing durability, and enabling reliable performance across various driving conditions, including rugged terrains and challenging environments commonly encountered in commercial applications.

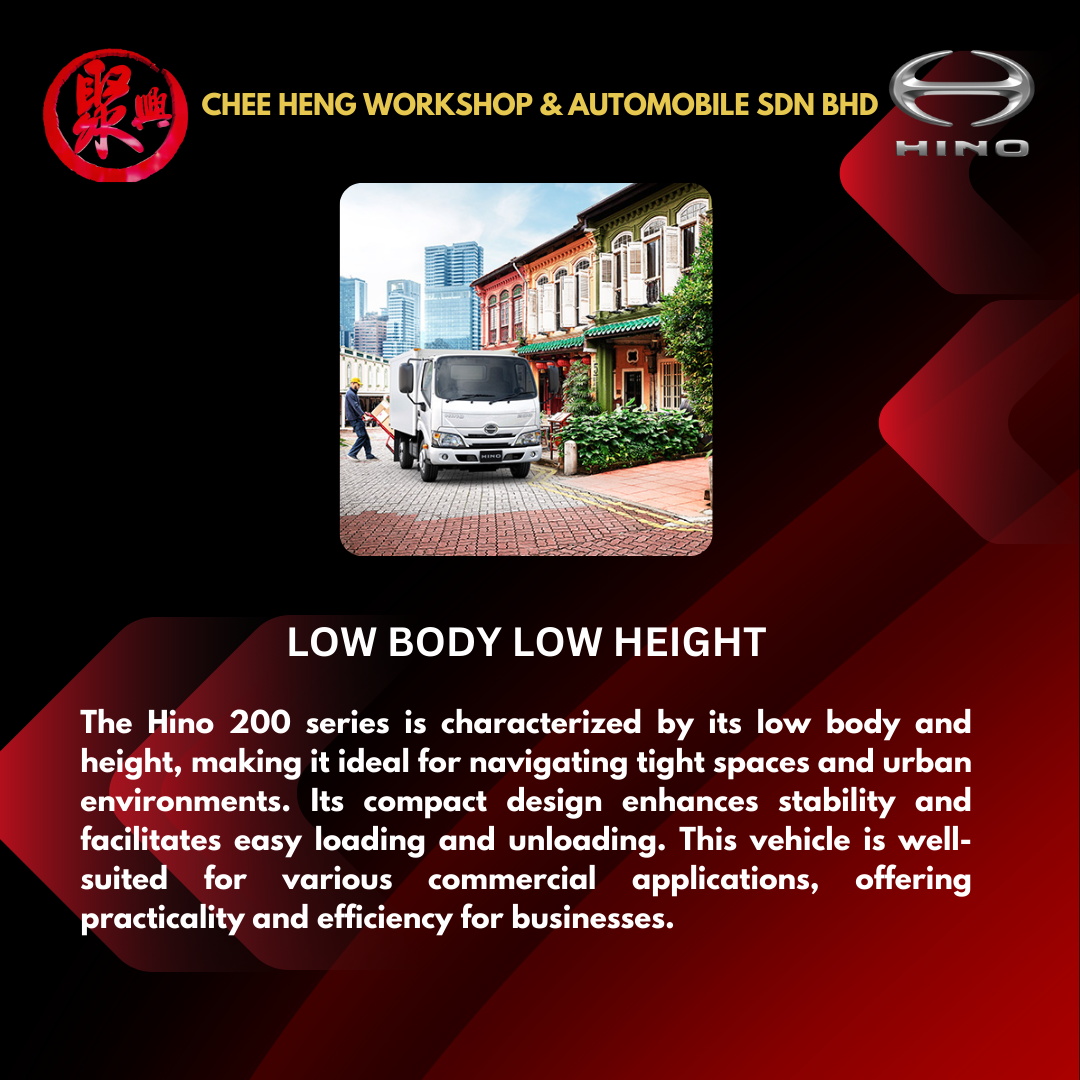

The Hino 200 Series Low Body Low Height variant is a specific configuration of the Hino 200 Series trucks designed for applications where a lower overall height is crucial. This variant is typically used in scenarios where there are strict height limitations, such as underground parking garages, areas with low overhangs, or for easier access to loading docks with lower clearance.

Key features of the Hino 200 Series Low Body Low Height variant may include:

1. Reduced Overall Height: Designed to be lower than standard models to meet height restrictions.

2. Payload Capacity: Despite the lower height, it retains a competitive payload capacity suitable for various light to medium-duty applications.

3. Engine and Performance: Usually equipped with efficient engines that balance power and fuel economy, suitable for urban delivery and similar tasks.

4. Customization Options: Depending on the model and market, there may be additional customization options available to tailor the truck to specific business needs.

5. Safety and Comfort: Often includes features aimed at driver comfort and safety, essential for long hours on the road.

If you are considering this variant for a specific use case, it’s advisable to check with Hino dealers or the manufacturer directly to get detailed specifications and ensure it meets your operational requirements.